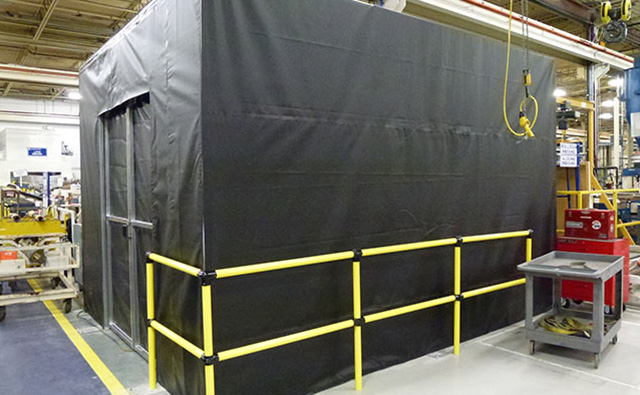

Soper's Softwall Enclosures

Soper's Stationary Softwall Enclosures effectively contain and control processes that can contaminate the workplace environment. Their softwall enclosure booths start with a basic frame concept. Additional options such as lights, windows, and front curtain panels can be added.

Soper's Enclosures easily integrate with third party dust collection or cross flow filter modules. Custom-designed to meet your specific application, they can also incorporate retractable roof panels to accommodate overhead crane cables or large bi-folding doors to maximize opening to load large pieces.

Features

- Modular in design, and tailored to interface with specific material handling and processing operations

- Easily integrates with third party dust collection fan filter units

- Full range of Softwall fabric panels available to meet a variety of unique requirements

- Velcro or fixed mechanical fastening options

- Optional access/door/roof panels

- 1.5" or 2.0" sq. galvalume steel tubing frames

- No painting required

- Easy thru-bolt field assembly

Benefits

- Reduce dust, fumes, and airborne particulate

- Improved employee health & safety

- Increased productivity

- Easy to install, dismantle, and relocate

- Economical

Applications

- Work stations

- Grinding

- Welding

- Sand or soda blasting

- Chemical stripping

- Blackout inspection

- Fabricating cells

- Assembly areas

- Painting rooms

- Creating cleanrooms or ISO quarantine areas. Learn more.

Advantages of Softwall Enclosures

Cost

Traditional rigid wall construction can cost anywhere from $8 to $35 per square foot. Soper's Softwall systems cost a fraction of what it cost to build a traditional rigid wall, with the flexibility to easily expand in the future.

Flexibility

Traditional rigid wall construction is difficult to modify or move. Soper's Softwall partitions and enclosures can be easily disassembled and reinstalled or reconfigured elsewhere to accommodate new requirements.

Installation

Installing a rigid wall can be expensive, messy and time consuming. Soper's Softwall Partitions and Enclosures can be installed quickly with little or often no downtime, meaning minimal interruption to production.

Cleanroom Enclosures

Soper's Softwall materials can be used to create completely controlled cleanroom enclosures or isolation areas, from non-specified environmental rooms (also known as white rooms or gray rooms), to fully-specified ISO class cleanrooms. Soper's Cleanroom Enclosures are most commonly used to create a positive air pressure environment, and are easily integrated with third-party fan filter modules.

Features

- Manufactured of Clear View Polyvinylchloride (PVC)

- Anti-static, high temperature, chemical resistant materials available

- Rugged, anodized aluminum frame system

- Modular design enables multiple configurations

- Completely self-supporting or suspended from existing overhead structure

- Increase cleanroom classification by using drop-in HEPA filter units

Retractable Enclosures

The ideal solution when floor space is limited or when beam cranes require unobstructed overhead space (complete with both positive and negative pressure 3rd-party attachments for environmental and clean room type applications). A Soper's Retractable Enclosure is compact, retracting to 25% of its extended size. The enclosure can be easily retracted manually or automatically.

Applications include: Grinding Booths, Blackout Inspection, Prep Stations, and Cleanroom Assembly or Rework Areas

Features

- Rugged galvalum frame modules designed for industrial plants and facilities

- Each "scissored" module comes fully assembled complete with thru-bolt pre-drilled holes to add multiple modules

- A full range of softwall panels is offered to meet a multitude of unique requirements

Flame Retardant Materials

Local governments uphold strict codes and regulations that determine classifications of flame retardant fabrics. There are many testing methods and agencies that perform these tests including the National Fire Protection Association (NFPA) and American Society for Testing and Materials (ASTM). Soper's can design your custom solution to meet Class 1 ASTM E 84 or NFPA 701 flammability specifications and building code requirements by matching the right fabric to your application.

| Material | Specification |

|---|---|

| Clear View Polyvinylchloride (PVC) | Select VCP materials meet NFPA-701, CAN/ULC-S109 and Class 1 ASTM E 84 flammability specifications. |

| 14 Mil Clear Polyvinylchloride (PVC) | PVC is a popular clear vinyl that is cost efficient, flexible, and durable and meets the NFPA-701 fire rating. |

| Woven Polyethylene | Woven polyethylene fabric provides extremely high tensile and tear strength in relation to its light weight and meets NFPA-701 and Class 1 ASTM E 84 flammability specifications. |