Laminar Flow Hoods

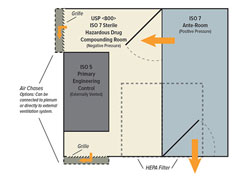

Laminar airflow is air moving at the same speed and in the same direction. A laminar flow clean room typically moves air from filters in the ceiling down to the floor and out through an exhaust or recirculating air vent. This forces any particulate to the floor and out of the cleanroom to reduce the probability of contamination. To make a space cleaner, we increase the velocity of the air movement to improve this effect. The smaller the volume to clean, the less total air movement is required, which reduces the overall cost of the operation.

For contamination-sensitive processes, we can achieve a much higher level of cleanliness by reducing the air volume of the critical environment within a laminar flow bench. Whether a vertical or horizontal flow, laminar flow benches provide a localized ISO Class 5 (Fed. Class 100) area for added protection against contamination. Some examples of applications include laboratories, 797 drug compounding, IV preparations, electronics manufacturing and medical device assembly. Any process can be made cleaner within the confines of a laminar flow bench, regardless of it being in a clean room or not.

Things to consider when selecting a laminar flow hood:

- In cleanroom environments, consider air flow from clean to dirty. If work is done above the work surface, such as adding a sample to test tubes, vertical flow is best because the air is cleanest closest to the filter or where the sample is accessed. For applications such as agar samples, the most critical samples should be near the filter in a horizontal flow bench so they occupy the cleanest space and hands do not pass over them.

- When using a cabinet, let it run for several minutes before introducing samples to assure that all particulate is swept out of the area.

- Keep in mind the footprint of a unit, many of these benches are fully welded and shipped crated. If they will have to be brought in through narrow doorways or upstairs, it may be best to select a modular unit that ships knocked down.

Shop Laminar Flow Workstations

BenchtopLaminar Flow Hoods

Quickly and easily turn any workbench, stainless steel table or cart into a laminar flow workstation by adding a benchtop unit. Simply plug it in, and you have ISO Class 5 (Fed. Class 100) environment.

FreestandingLaminar Flow Hoods

Our freestanding laminar flow benches and hoods are available in two styles; models that include an attached work surface, or models with an open bay to accommodate an existing work bench or stand.

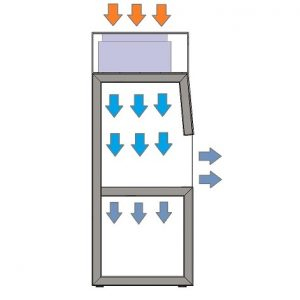

VerticalLaminar Flow Benches

Vertical laminar flow hoods direct air downward, sweeping particles and micro-contaminants out through the front access area to settle on a work surface or floor, faster. Ideal for areas where floor space is limited.

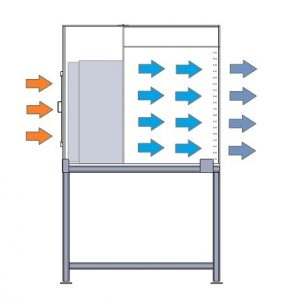

HorizontalLaminar Flow Benches

Horizontal laminar flow benches direct air in a straight line from the filter face and often have a larger footprint. They are ideally suited to laboratory work, testing, manufacturing, inspection, or pharmaceutical operations.

Horizontal vs. Vertical Laminar Flow Workbenches

Benefits of Vertical Laminar Flow Workstations

- Shallower hood requires less floor space

- Ideal for compounding sterile products

- Sash provides a barrier in front of the operators face, so the air isn't blowing directly at them

- Filter located on the top of the unit for easy access

- Less turbulent effect from the air hitting objects or processing equipment

- Less cross-contamination of items on the work surface

Benefits of Horizontal Laminar Flow Workstations

- Air exits the unit without hitting a work surface, so there is little to no turbulent effect

- Air flows straight out, removing the need for a sash and giving the operator more room to work

- Ideal for low profile mixing operations, because items accessing samples, like gloves and equipment, are downstream from the samples near the filter