ESD Workbenches

What is an ESD Workbench?

ESD Workbenches establish a zero-potential ground between the floor/earth, a worksurface, and a user. Conductive ESD-safe surfaces channel, slow down, and shield electrically sensitive devices from defects and device failure. For electronics manufacturing, a worksurface resistance point to point is ideal above 1.0 x 106 but below 1.0 x 109. Modular add-ons and features such as heat resistance surfaces provide ideal fit and function for hand assembly lines. Typically these benches provide a central receptacle for connecting ground points from ESD floor mats, wrist straps, and other ESD accessories.

When Do You Need One?

Safe workstations for flat-panel, medical device, printed circuit board, and semiconductor manufacturing require:

- A Conductive Worksurface (1) that evenly distributes electron charges and uniformly neutralizes excess charges.

- As well as grounding point, such as a Workstation Grounding Block (2) or a Common Point Grounding Cord to connect wrist straps, ESD garments, and anti-static workstation mats.

- A Grounding Point (3).

Shop ESD Workbenches

ESD Workstation Accessories

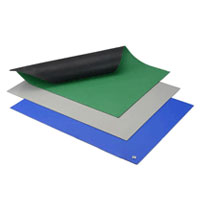

Do You Need a Benchtop Mat with an ESD Work Surface?

Use of a Benchtop ESD Mat on an ESD work surface is not required, however, the rubber ESD table mats can provide a soft surface for electronic components that may be damaged by subtle or repeated impact on a work surface. ESD work surfaces should always be grounded to a common ground point, and never daisy chained.

The most common precursor to ESD events is not faulty equipment, but instead operator error such as setting sensitive devices on non-ESD surfaces or failure to follow proper grounding procedure. ESD benches provide a permanent stand in for ESD mats and reduce the likeliness of user-driven ESD events, such as hastily setting down an ESD device on a non-ESD workstation.

See our Guide to ANSI/ESD S20.20 and learn how ESD workbenches and ESD work surfaces enable ESDA certification, or find specific information about resistance measurements for ESD worksurfaces.

Do You Need an ESD Chair?

Non-conductive chairs create opportunities for user error, even when using ESD flooring, such as when a user rests their feet on something besides the floor such as a separate footrest or stool rail. If both of a user’s feet do not touch an ESD floor or ESD mat, and the user is not grounded with an ESD strap, static will discharge. Likewise, if the user is not wearing ESD footwear or grounding straps, the insulative character of standard shoe soles will impede the effectiveness of an ESD chain.

An ESD chair dissipates static potential when sitting down, standing up, or in the chance that feet separate from the floor until both the operator and the chair share the same charge. Dissipative materials and static free fabrics allow charges to dissipate through ESD through ESD casters or drag chains.

Does a Chair Need ESD Casters if You Have a Drag Chain?

Grounding chains provide a dedicated connection that prevents charge buildup when a cart or chair moves across the floor. As demonstrated in this video, a static control drag chain may only be 20-50% effective. In controlled environments, a drag chain is much more difficult to clean and accumulates dirt and particles more rapidly. The dirtier an object the less likely it is to provide conduction. Specially designed ESD chains make contamination more feasible. Problematically, static control chains are always subject to snags and if the chain is not heavy it enough conduction may be lost.

The advantage of ESD casters is that the connection to ground is much more stable and reliable. Chairs with conductive ESD casters maintain almost perfect connection with the floor and provide four points of continuous connection. Casters are also a much better solution for clean-forward environments.

Conductive chair mats provide a continuous path to ground prevents chair casters from damaging or wearing out ESD flooring. The conductive circuit remains continuous while also preventing scratch and scuff marks.

ESD Floor Mats & Runners

ESD floor mats protect sensitive equipment and components from damage from electrostatic discharge. Ergonomic mats extend standing comfort for operators at processing or assembly points. ESD floor runners allow safe and comfortable workflow when moving sensitive items throughout a facility or EPA areas. The low profile design allows easy passage through corridors for foot and cart traffic or complete pathways ways along equipment or assembly lines.

When Do You Need ESD Flooring?

ESD flooring is often deployed when ESD wrist straps impede work. Problematically, if an operator were to remove their feet from the floor, or place their feet on a footrest, there is potential for discharge. Because wrist straps can often reduce mobility and workflow, a combination of ESD chairs and static control flooring improves both operator freedom and procedural compliance.

Conductive flooring systems provide the lowest charge generation and quickest charge dissipation for an ESD production environment. The flooring is grounded through a copper strip which connects to the flooring to a grounded connection such as a wall outlet.